Rail transfer carts, also known as rail-guided transfer trolleys or rail-bound transfer carts, are specialized material handling vehicles designed to move heavy loads along a fixed rail system. These carts are commonly used in various industrial settings, including manufacturing plants, warehouses, and assembly lines, where the transportation route is predefined and repetitive. Here’s a detailed look at rail transfer carts

Key Features

- Design and Construction

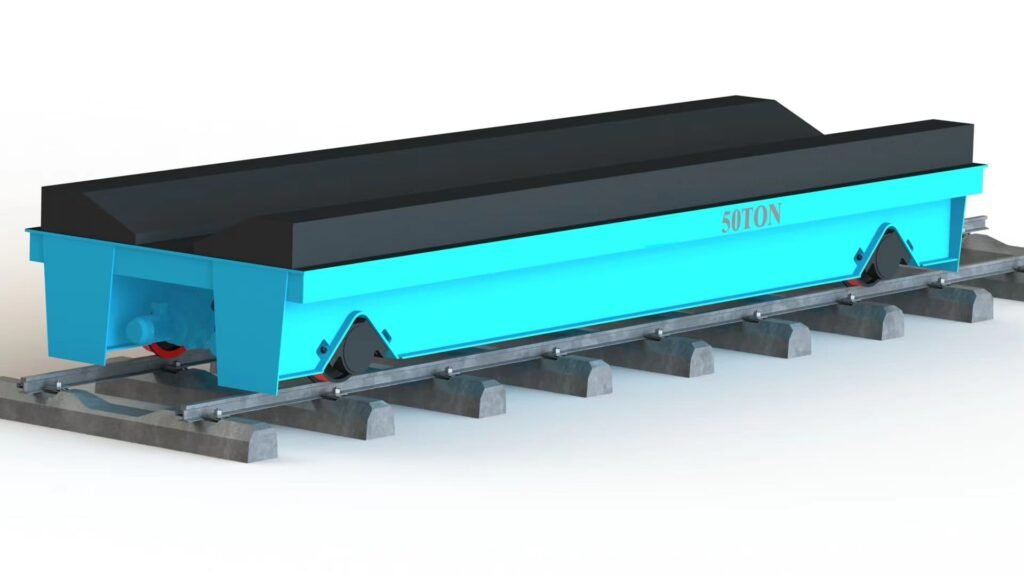

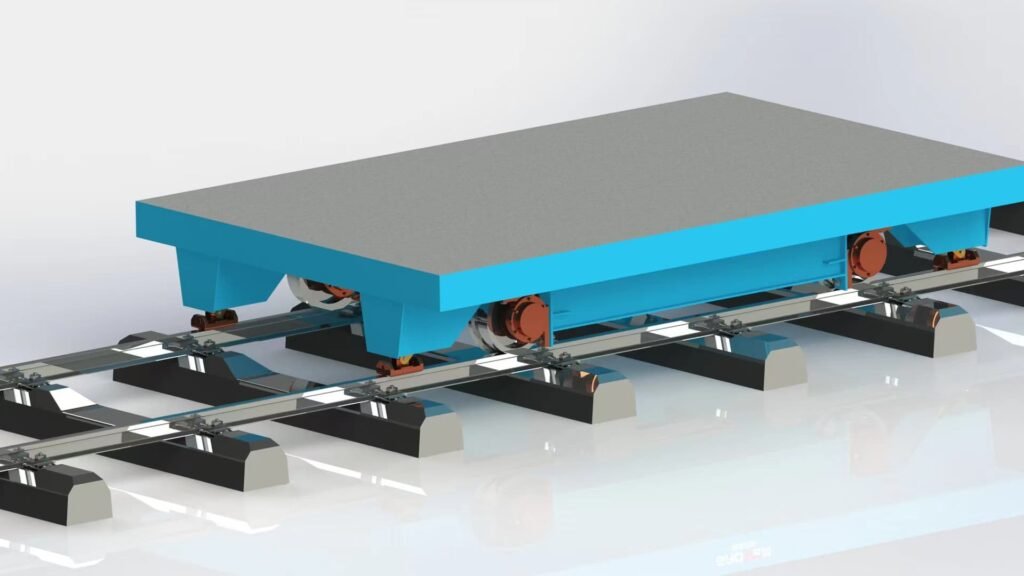

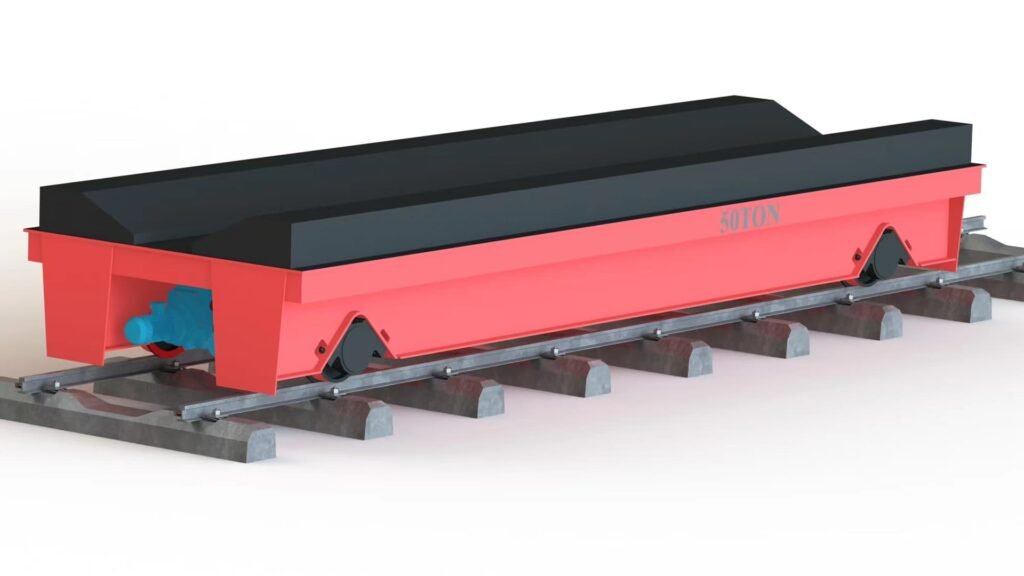

Sturdy Frame Made of high-strength steel to handle substantial weights and ensure durability.

Rail Wheels Fitted with wheels designed to run on steel rails, providing stability and smooth movement. - Power Source

Electric Powered Typically powered by electricity, either through an onboard battery system or connected to the facilitys power grid via a cable.

Battery Operated Offers flexibility within the rail network without the need for constant power connection.

Cable Reel Powered Uses a cable reel to supply continuous power from a fixed point. - Load Capacity

Can handle a wide range of loads, from a few tons to several hundred tons, depending on the carts design and application. - Guidance System

Rail-Guided Moves strictly along the installed rails, ensuring precise and predictable paths.

Functions and Applications

- Material Handling

Efficiently transports raw materials, work-in-progress, or finished products between different stages of production or storage areas. - Assembly Line Integration

Transfers components along various stages of an assembly line, particularly in automotive, aerospace, and heavy machinery industries. - Warehouse Logistics

Facilitates the movement of heavy items in warehouses, often integrated with automated storage and retrieval systems (AS/RS). - Loading and Unloading

Moves materials between different parts of a facility or to/from transportation vehicles such as trucks or other rail systems.

Types of Rail Transfer Carts

- Single-Rail Carts

Run on a single track, typically used for straightforward linear movement. - Double-Rail Carts

Operate on parallel tracks, providing enhanced stability for very heavy or oversized loads. - Turntable Rail Carts

Equipped with a turntable to switch tracks or change directions, allowing for more complex movement paths within a facility. - Custom Rail Carts

Tailored to specific industry needs, which may include special dimensions, capacities, or additional features such as tilting platforms or rotating decks.

Advantages

- High Load Capacity

Capable of transporting extremely heavy and bulky items with ease. - Precision and Safety

The fixed rail system ensures precise movement and reduces the risk of accidents associated with free-moving vehicles. - Efficiency

Ideal for repetitive and high-volume transport tasks, enhancing overall operational efficiency. - Customizability

Can be designed to meet specific requirements, including size, shape, and additional functionalities. - Low Maintenance

Generally robust and durable, requiring minimal maintenance compared to other types of transport systems.

Limitations

- Fixed Path

Limited to predefined routes, lacking the flexibility to change paths or routes easily. - Infrastructure Requirement

Requires the installation of a rail system, which can be costly and time-consuming.

Use Cases

- Steel Plants

Moving large steel coils or slabs between processing areas. - Automotive Manufacturing

Transporting car bodies or large components through various stages of assembly. - Shipbuilding

Handling heavy ship sections or components within the yard. - Mining Operations

Moving extracted ore or heavy equipment between different processing areas.

Rail transfer carts are essential in environments where high-capacity, repetitive, and reliable transportation of heavy loads is required. Their robust design and ability to integrate with industrial processes make them a valuable asset in many heavy-duty material handling applications.